the fundamentals of hardness testing k hermann|Introduction to Hardness Testing : OEM Contents. Chapter 1 The Fundamentals of Hardness Testing. 1. Chapter 2 Hardness Measurement of Metals Static Methods. 25. Chapter 3 Dynamic Test Methods. 67. Chapter 4 . Resultado da Plantão Rv, Rio Verde, GO. 9,117 likes · 863 talking about this. página de notícias e entretenimento do sudoeste goiano

{plog:ftitle_list}

ED Celandine Font Free Download. ED Celandine is a blackletter font that masterfully blends modern trends with timeless elegance. Its minimalist design retains the classic blackletter aesthetic while introducing a contemporary touch, making it a versatile option for various projects.

This chapter discusses the history of hardness testing and defines the term hardness. It describes the interrelationship between material structure and hardness and the relationships between hardness and other mechanical material properties. This chapter discusses the history of hardness testing and defines the term hardness. It describes the interrelationship between material structure and hardness and the .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been .

Contents. Chapter 1 The Fundamentals of Hardness Testing. 1. Chapter 2 Hardness Measurement of Metals Static Methods. 25. Chapter 3 Dynamic Test Methods. 67. Chapter 4 . It reports on technical developments such as the introduction of image processing in the Brinell and Vickers method, the adaptation of hardness testing machines to process-oriented testing conditions, and the development .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. CHAPTER 1 The Fundamentals of Hardness Testing. The History of Hardness Testing. The Term Hardness. Interrelationship Between Material Structure and Hardness. .

The Fundamentals of Hardness Testing

The principal purpose of the hardness test is to determine the suitability of a material for a given application, or the particular treatment to which the material has been subjected.

Hardness Testing: Principles and Applications. Editor: Konrad Herrman. Hardcover. Product code: 05331G. ISBN: 978-1-61503-832-9. Provides an overview of the hardness testing of metals, plastics, rubber, and other .Contents. Chapter 1 The Fundamentals of Hardness Testing. The History of Hardness Testing. The Term Hardness. Interrelationship Between Material Structure and Hardness. .

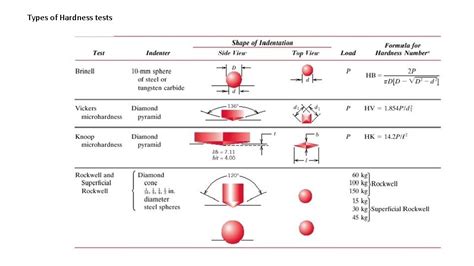

The conventional testing methods (Rockwell, Vickers, Brinell, and Knoop) used for testing of metals are based on the idea that hardness represents the resistance against permanent plastic deformation of the material to be tested. However, elastic deformation must be considered in hardness measurement of elastomers.

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals--Rockwell, Brinell, and Vickers--were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests. This .

Introduction to Hardness Testing

Total test force/N: Constant K: Hardness range: application examples: A: Diamond circular dimension: 100: 500: 600: 100: 60~85: High hardness thin parts and cemented carbides: B: φ1.588mm steel ball: 900: .

Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The . There are many hardness test methods that are performed by an array of techniques, from comparative references to scratch testing and indentation methods [1,3]. While hardness numbers have repeatable correlation to material strength, efforts to reduce hardness testing to a universal, fundamental physical test have not been successful.

Chapter 1 The Fundamentals of Hardness Testing; The History of Hardness Testing; The Term Hardness; . Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals-Rockwell, Brinell, and Vickers-were developed between 1900 and 1925, numerous technical innovations . Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it.

The first standard developed to address a test method for measuring “Universal Hardness” (now Martens Hardness) was DIN 50359-1 to -3 in 1997–1998 [32]. It defined the test method, as well as the methods for the verification and calibration of hardness testing machines.Hardness Testing: Principles and Applications. Edited by Konrad Herrmann .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it.The determination of material hardness is not a fundamental property like mass or length, but a material's response to a specific test method. It's fascinating to note that the result can be related to properties such as strength or wear resistance. . Brinell Hardness Testing: Involves applying a known load to the surface of the test sample . The main problem with hardness is that it’s not a well-defined property. The value obtained during testing of a given sample is different for different types of test, and also for the same test with different conditions. Identical hardness numbers can be obtained from materials exhibiting a wide range of yielding and work hardening .Hardness Testing: Principles and Applications. Edited by Konrad Herrmann. Konrad Herrmann .

Herrmann K. (ed.) Hardness testing. Principles and applications

Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection .Fundamentals of Rockwell Hardness Testing Fundamentals of Rockwell Hardness Testing Fundamentals of Rockwell Hardness Testing Principle of Test Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to .

Hardness testing. Principles and applications.jpg)

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .The chapter reviews methods used to check and calibrate hardness testing machines and indenters and the use of hardness reference blocks for verification and calibration of test machines. It also addresses conversion of hardness values determined by one method to equivalent values for a different method.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . DOE Fundamentals Handbook, Volume 1 and 2. January 1993. U.S. Department of Energy, Material Science. DOE Fundamentals Handbook, Volume 2 and 2. January 1993. The main problem with hardness is that it’s not a well-defined property. The value obtained during testing of a given sample is different for different types of test, and also for the same test with different conditions. Identical hardness numbers can be obtained from materials exhibiting a wide range of yielding and work hardening .

automated realisation gain the widest application in hardness testing of metals. In order to guarantee the accuracy of the hardness testing machines, a direct calibration of the test force, the depth measuring system, the indenter and the test cycle and an indirect calibration with hardness reference blocks is prescribed in ISO 6508-2.[1] Hardness testing is a fundamental material science technique that measures a material’s ability to resist deformation. It is an essential parameter in the manufacturing industry, as the hardness of a material can affect its strength, durability, and performance. The hardness test is a way to assess the quality of a material, determine its . In this interview, AZoM speaks with Clemex about hardness testing, the different types, and its various applications. What is hardness testing? Fundamentally, hardness testing determines the resistance a material exhibits in response to the permanent deformation of another material’s penetration. If I take a piece of metal and rub something . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .

moisture meter direct

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that have been developed to measure it. Hardness, as defined in the first chapter, is a type of resistance to deformation, the roots of which lie in the packing density of atoms and the bonding forces that keep them in place. Buehler is a recognized leader in materials preparation, testing, and analysis, ensuring highly credible and practical insights. This source is valuable for readers seeking a thorough understanding of hardness testing techniques and their applications. 2. Academic Journal: “Advancements in Hardness Testing Techniques: A Review .

The Vickers hardness test and Knoop hardness test are commonly used here, following the ASTM standard for micro Vickers hardness testing by ASTM E 384. These methods are ideal for analyzing thin coatings or microstructures, where precision is essential. For macro hardness testing, a higher force is used to create a larger impression. To determine dynamic hardness, the indenter is forced under high loading rate which leads to impact or chock the test material. Thus, the indenter could be shot the tested material like a projectile onto the target surface (Low 2006; El-Ezz 2007).The test material must be permanently deformed, so the kinetic energy should be chosen to assure plastic .

moisture meter daraz

Resultado da Pinned Tweet. Ami Chan Cosplay. @AmiChanCosplay. ·. Feb 14, 2022. Dont forget to smile even if it’s not a good day, everything will be alright .

the fundamentals of hardness testing k hermann|Introduction to Hardness Testing